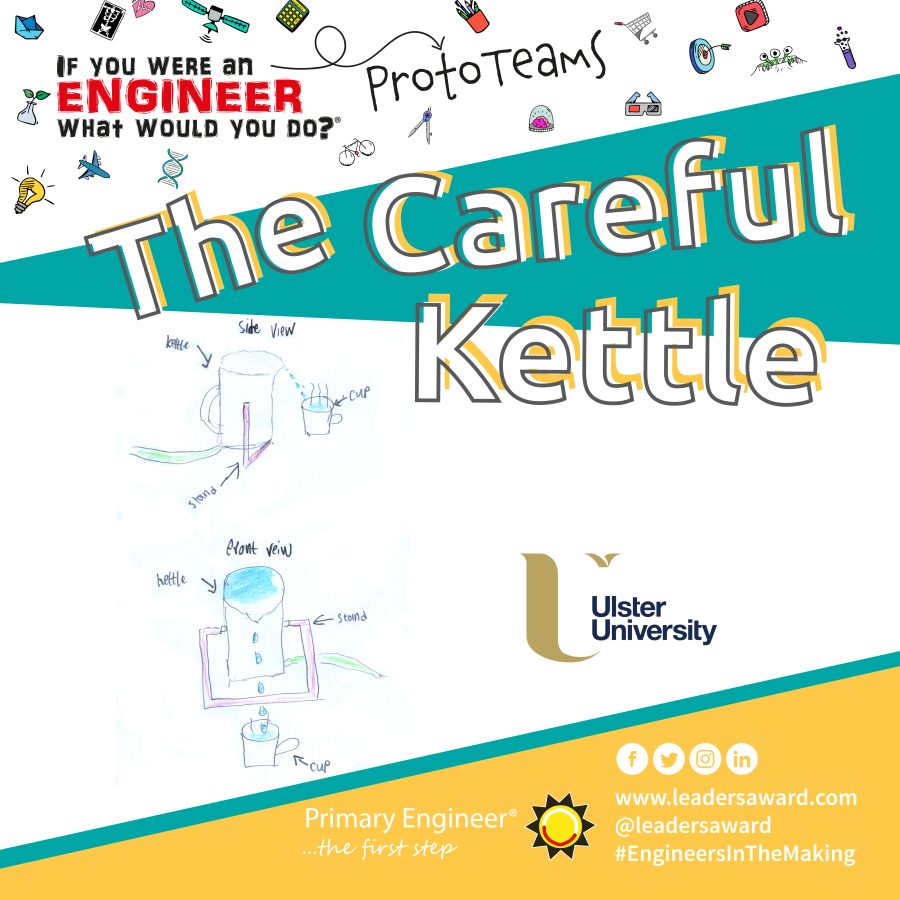

Ulster University creating The Careful Kettle

Ulster University will turn Year 7 pupil Thomas’ Careful Kettle idea into reality for their prototype build as part of a continued partnership between Ulster University and Primary Engineer.

Ulster University are a University Prototyping Partner for Northern Ireland as part of our annual engineering competition which asks pupils aged 3-19 ‘If you were an engineer what would you do?’ and encourages pupils come up with creative solutions to real-world problems.

Ulster University have selected his design to turn into a prototype over the 2023/2024 academic year which will be unveiled at the next Northern Ireland Awards Ceremony and Public Exhibition during the Summer term.

They chose this design because this idea will really help people who are elderly or have medical conditions and will help them use the kettle carefully without risk of injury.

Beginning the prototype

The ProtoTeam at Ulster University team met in December to discuss their plans to start manufacturing and design the prototype following the project prompts and Thomas’ drawings.

In relation to material, they have decided they will be using 3D printing for 70% of the stand which means it will be plastic, the other 30% of the product will be metal which we will apply on the base to allow for extra stability. They plan to melt the metal bars into the plastic stands.

For the size, they will be using a factor of safety (FOS) which is used in many manufacturing projects to ensure the safety of the material. This means that they will be designing this product to carry times 3 of the weight it is built for. So, let’s say an average kettle weighs around 2-3 kgs, this product will be designed to handle times 3 of that weight therefore the FOS will be 3.

For the colour, Thomas did not specify the colour he wants but one of the ProtoTeam members has worked with old patients with medical problems and she said the colour red will be the best to go with in order meet the target audience.

For extra features, the team have all decided they want to add an insulating material like the ones people have on coffee cups to prevent the flow of heat when the boiling water is inside. To do this, they plan to either make one or buy one and attach it to the kettle. Also, they plan to use rubber feet at the bottom of the stand.

The next step is to have all the CAD drawings ready for printing then get printing and have a prototype done for examination and testing.

We can’t wait for the next update on this prototype!