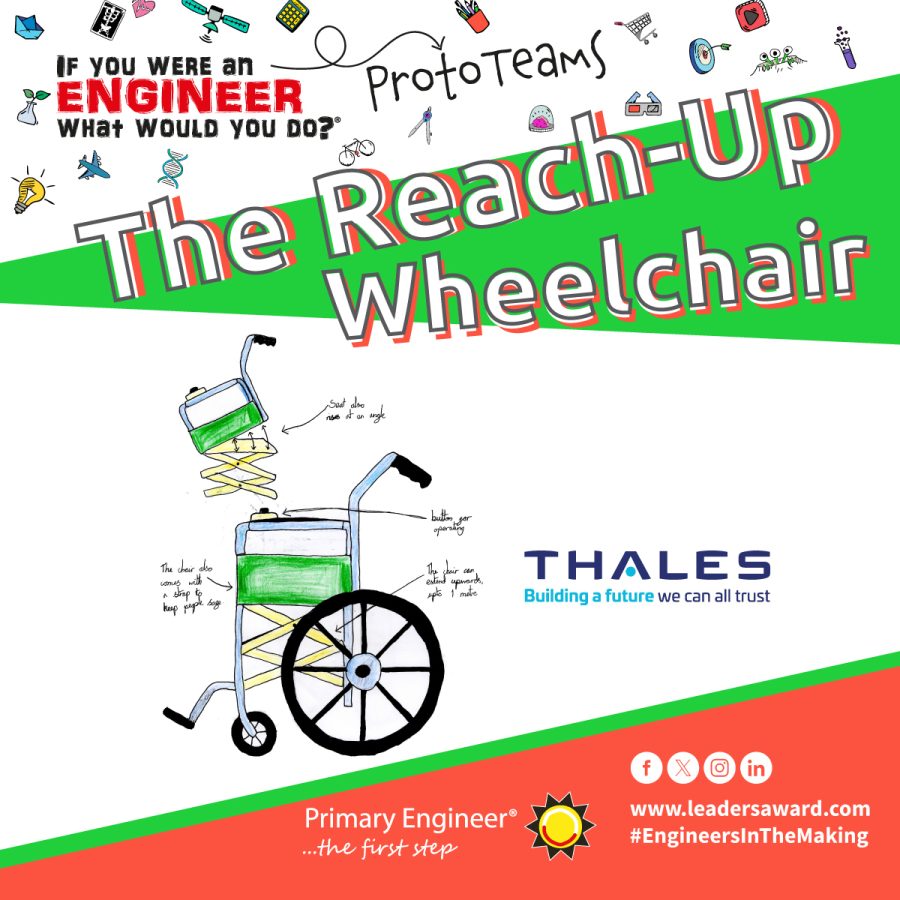

Thales Templecombe creating the Reach-Up Wheelchair prototype

Thales UK are a national partner for our Leaders Award competition which asks pupils aged 3-19 the question “If you were an engineer, what would you do?”. This year Thales UK will be creating 6 prototypes across 5 of their UK sites, in total turning 6 pupils’ ideas submitted to our Leaders Award competition into a working prototypes over the 2024/2025 academic year.

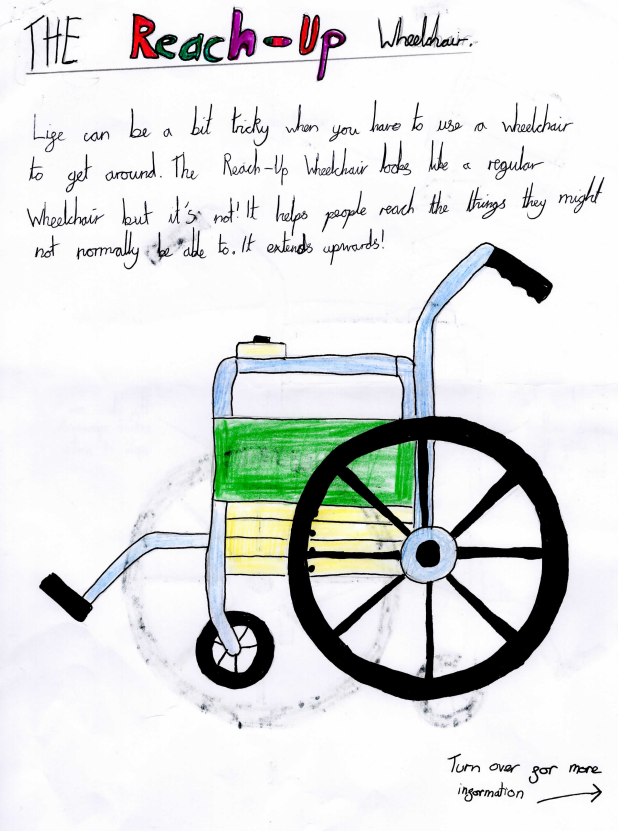

Pupil designer, Sophie, will see her engineering idea ‘The Reach-Up Wheelchair’ turned into a reality by Thales Templecombe. Her idea makes life a little easier for wheelchair users, helping them reach the things they might not normally be able to. The chair features a button to extend the chair upwards up to 1 metre, raise the seat at an angle plus a safety strap.

Introduction to the ProtoTeam

The Thales Templecombe prototeam consists of six members, each bringing different skill sets to the table:

- Freya Morris – Project Manager

- Daniel Fearn – Systems Engineer

- Zacary Leighton-Ditchburn – Mechanical Engineer

- Harris Cutts – Manufacturing Apprentice

- Prasanna Lamgade – Mechanical Engineer

- Ben Mammatt – Hardware Apprentice

Project Overview

From initial estimates of a motor operated scissor lift, the students intended design would be too costly and hazardous as a product. As such an alternative design has been chosen.

An air jack or air bag, will be our method for lifting the user. Air fills the bags via a compressor powered by a battery and expands – raising the user. Stability will be provided by a metal rod within the air jack and utilising the sides of the scissor lift to lock the user at the intended height for safety.

A linear actuator will be used as the tilt method for the design. This is a simple and cheap method of tilting the user for ease of access.

Ease of use luxuries will be added such as a panel to allow the user to adjust their height, angle and provide additional information.

Changes may occur to the design as it develops. Certain issues such as height limitations not meeting initial requirements, H&S issues or excessive noise from the compressor may cause a reflection in design choices which will be discussed with the student before any significant changes.

Starting the prototype

The team launched the project in January and now they are in the design stage, plan to meet the pupil designer a few times in the coming weeks to present initial ideas and make any necessary adjustments.

Next steps

We are looking forward to the next update!