The final update on the CWAB Prototype

At the end of GKN Aerospace’s last update, the C.W.A.B was functional but did not look the part. Based on Ben’s design and his feedback when visiting the GKN Aerospace Global Technology Centre, the team had two key tasks to complete before the unveiling:

• Design and assemble the bodywork

• Build a remote to control the CWAB

Bodywork

There were a few options available to the team for the bodywork. The roll-bars on the vehicle provided a natural support structure for fixing on the panels, along with some additional framework that was secured to the rear of the vehicle. Initial discussions considered the manufacture of the bodywork panels from a variety of materials to make use of the teams’ expertise and capability. These included plastic and metallic sheet materials, 3D printed materials, as well as lightweight composite carbon fibre panels. In the end, for time and cost reasons, it was determined that plastic sheet materials would be the most feasible. These sheets of plastic were cut to shape and then assembled onto the support frame.

A few key considerations were its ability to support the solar panel, accessibility to the water tank tap, ensuring the hose deployment arm could extend/retract, and having a removable wind-screen panel to allow access to the internal electronics.

Remote

To allow easy use of the C.W.A.B, the team were keen to stay faithful to Ben’s original design by having a very simple remote interface (one button!). They started by determining what the remote needed to do: send a signal to the electronics in the car to carry out the programme(s) stored on-board. It was decided to have two on-board programmes:

- Lower the hose arm, turn on the pump, turn off the pump, raise the arm

- Same as programme 1 but also with driving included

As a result, they connected two buttons (one for each program) to an Arduino circuit board that when pushed, would send their corresponding signal via a radio transmitter to a receiver on-board the car. When the car received the signal, it would begin the program. All of this was housed inside a 3D printed casing, with an antenna protruding out the top to boost the range of the signal.

CWAB On The Road

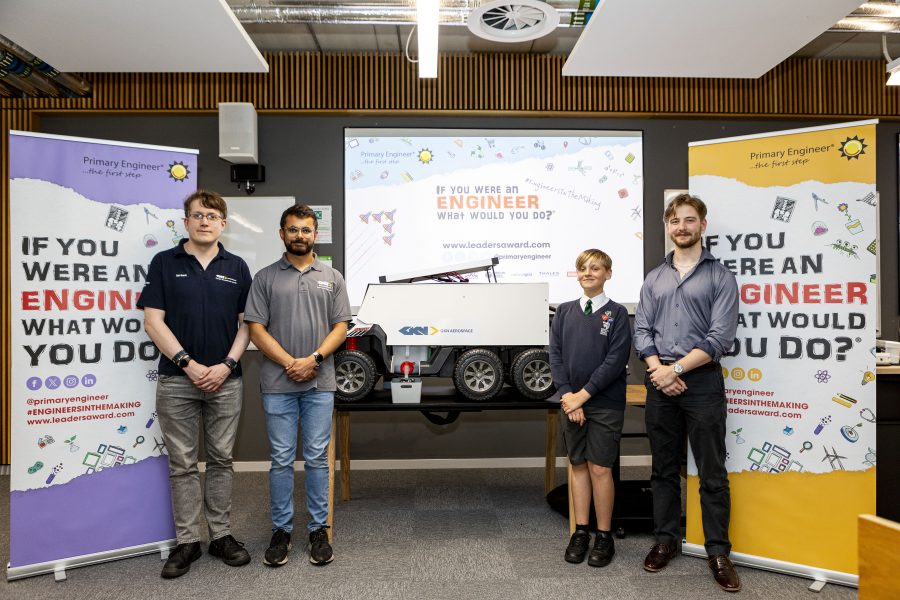

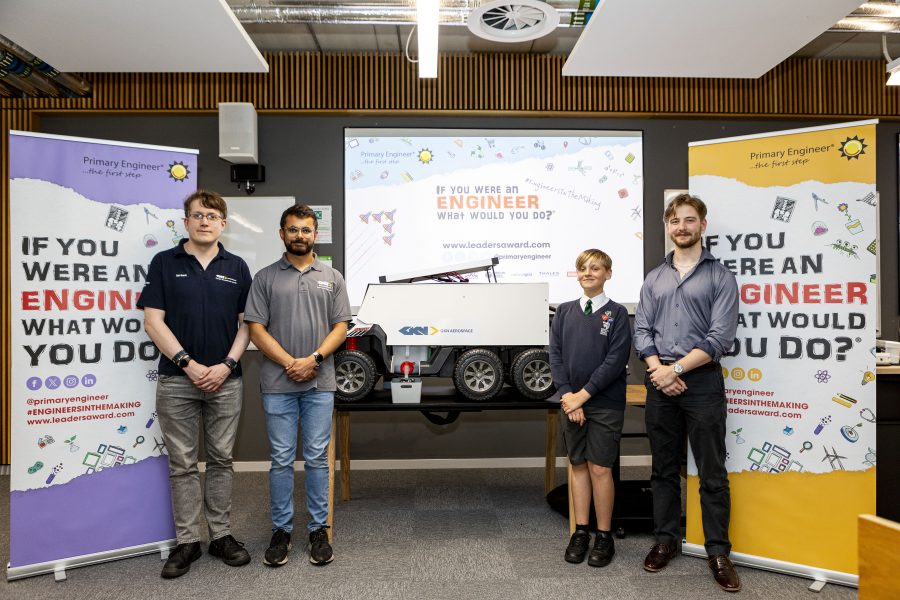

Having finished the bodywork and remote, the CWAB was ready to be unveiled at the South West Leaders Award exhibition held at the University of West England on the 5th July. The GKN Aerospace ProtoTeam gave a presentation at the event about their prototype, explaining the design, manufacture and operation of the C.W.A.B. before inviting Ben to the stage to unveil it for the first time! The team then gave a live demonstration of it in action.

The next event in the calendar was a visit to Ben’s school. The team gave an interactive presentation about GKN Aerospace and the wider industry, before revealing the C.W.A.B to Ben’s classmates and having a show-and-tell session where they could get up close, ask questions, and see it in action!

The final stop on the C.W.A.B’s summer tour was to Farnborough Airshow for the ‘Pioneers of Tomorrow’ STEM event. The prototype was showcased (next to a GKN Aerospace jet engine) alongside several other interactive STEM activities GKN Aerospace had been working on, with visitors coming and going from the GKN Tech Hall all day. This was a real highlight of the project, where all of the teams’ hard work was shown off to members of the public and the industry alike.

Upon finishing the project, the GKN Aerospace team reflected that ‘the project as a whole has been an amazing experience for those involved, inspiring us with the creativity and innovation of Ben and all of the other designs submitted to the competition, and hopefully allowing us to inspire some of the next generation of engineers to pursue careers in STEM’.